High efficiency, Sophisticated technology, and Uncompromising quality control lie at the very heart of Roche Energy's manufacturing philosophy. Whether battery pack or system integration, we create lasting value for our customers through strict IPQC and lean manufacturing.

As a trusted OEM partner, we understand that each client's needs are distinctive, and that's why we approach every project with a personalized touch. Roche Energy's production factory is equipped with multiple production lines to handle different types of customer purchase orders, ranging from manual lines to fully automatic production.

Most advanced welding technology across the whole industry provides extreme welding speed.

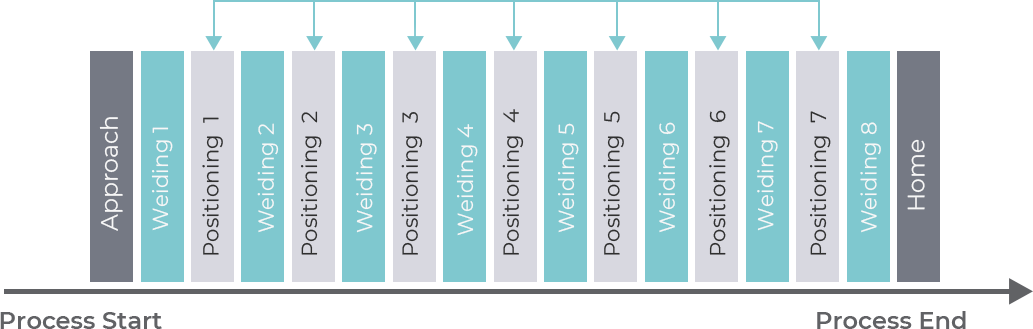

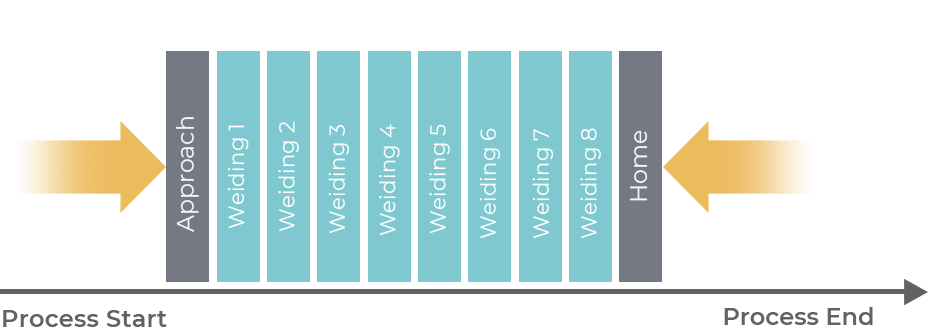

Traditional Welding

Fly Welding

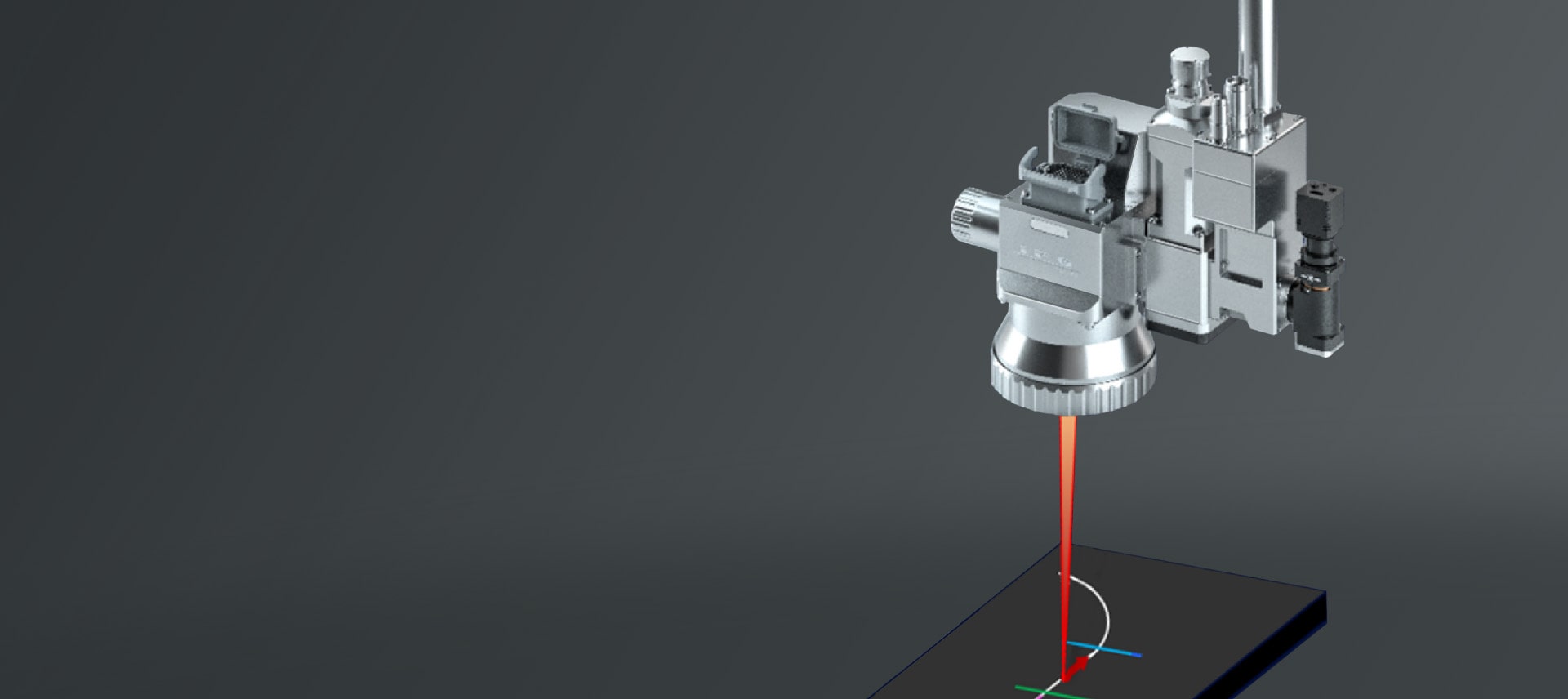

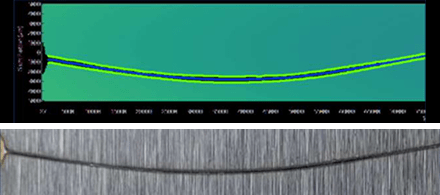

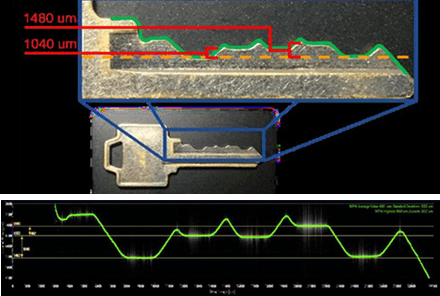

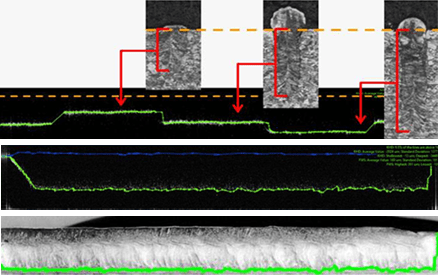

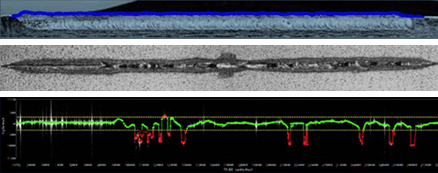

LDD Inline Coherent Imaging (ICI) technology is the only technology which can measure the following items at the same time.

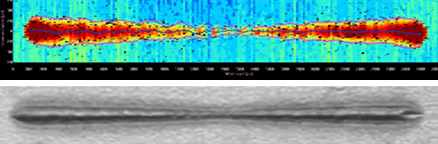

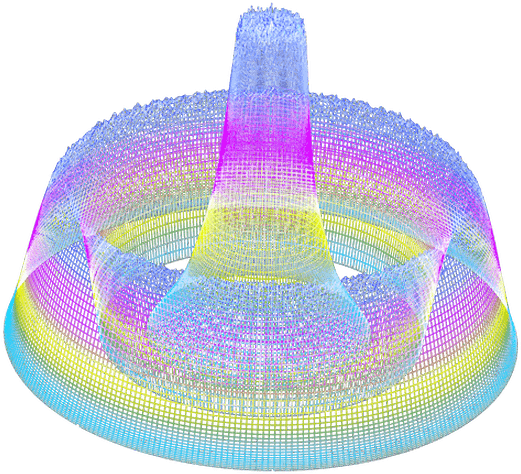

The annular beam technology employs an innovative approach aimed at mitigating the issue of spattering during welding processes. Specifically, it triggers a series of beneficial effects by directing an annular beam of light around the welding keyhole. Firstly, this annular beam rapidly vaporizes the metal liquid, generating metal vapor. As this vapor descends, it exerts a downward counterforce on the welding molten pool. This action helps open up the keyhole in the molten pool, resulting in a "Y"-shaped configuration, effectively suppressing surface fluctuations of the molten pool.

This "Y"-shaped keyhole not only reduces fluctuations but also covers the keyhole, preventing the normal outflow of plasma and thereby decreasing the likelihood of spattering. High-speed photography studies reveal that, in comparison to traditional laser beams, the annular beam successfully reduces the proportion of time and the keyhole remains closed from 24% to approximately 2%. The fewer keyhole closures occur, the lower the chances of spattering. Experimental results demonstrate that, compared to traditional laser beams, the annular beam significantly reduces spattering, lowering the probability by more than 92%, particularly eliminating defects caused by substantial spattering, such as quality loss and pitting.

Roche Energy incessant pursuit of quality and efficency are inseparable from its meticulously designed Manufacturing Execution System (MES). The system provides real-time feedback about manufacturing status and all component traceability for in-depth optimization.

Our MES dashboard records and traces every product as it is manufactured in our production process, providing essential information about its material and component makeup, from cell to module to pack. This allows us to track any faults in a product straight back to its origin. It also collects data to support our production optimization efforts and control the production process.

Process Engineering Control

Production Information Tracing

Product Quality Control

Production Process Control