In the manufacturing process of battery modules, the quality of battery connections is crucial for the overall performance of the module. In order to ensure high-quality connections, laser welding technology has become the mainstream choice due to its comprehensive, safe, and efficient advantages. However, laser inspection has always been a technical challenge for relevant professionals. With the maturity of Inline Coherent Imaging (ICI) technology, non-contact processes that truly achieve non-destructive full inspection for welding quality are gradually being applied to the online monitoring of laser welding. This is aimed at effectively addressing various shortcomings brought about by traditional inspection methods.

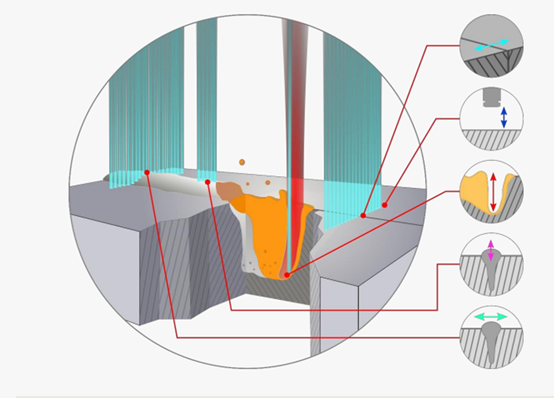

ICI technology has the capability to real-time record and transmit various parameter data at each welding stage, including workpiece height, cross-section, weld surface formation, penetration depth, and weld seam positioning, thereby achieving comprehensive monitoring of each welding process. In the event of part damage or welding defects, the system can immediately issue alerts to operators and the system, enabling timely corrective actions to be taken, and ensuring 100% quality assurance without adding extra cycle time.

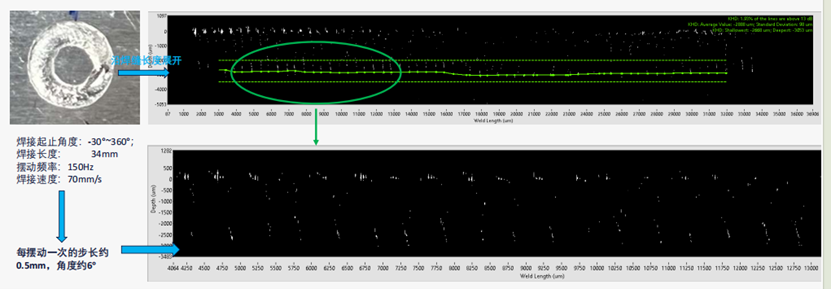

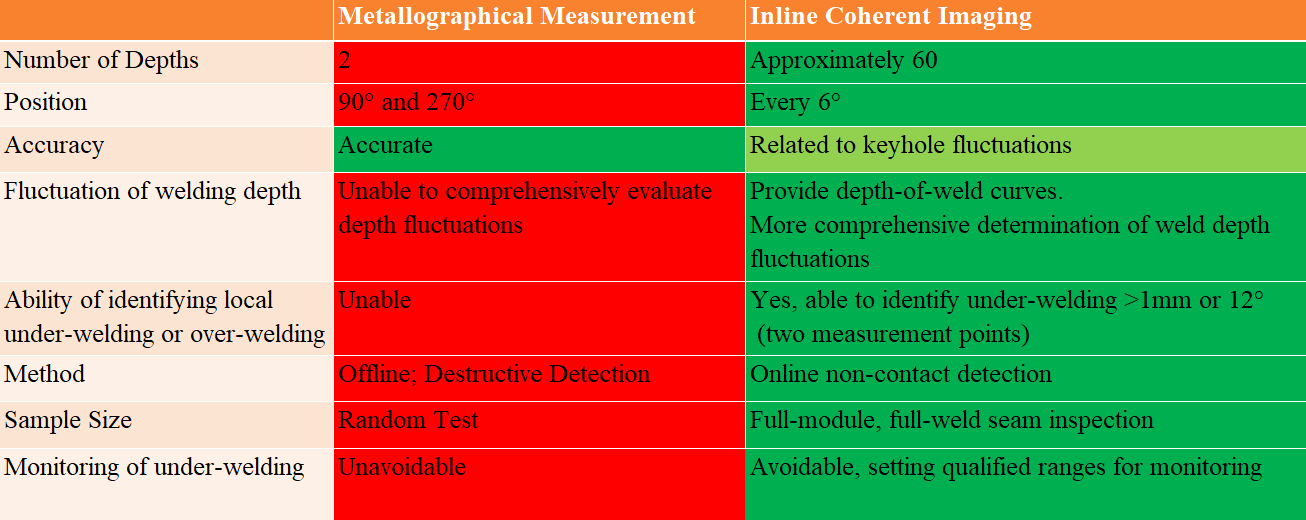

ICI technology can collect keyhole data in real-time, which means ICI conducts multiple depth measurements for each weld seam. These data points are integrated to generate a depth curve for the weld seam, providing a comprehensive reflection of every tiny fluctuation and variation in depth during the welding process. Any local abnormal depth, over-welding, or under-welding can be promptly detected, providing crucial evidence for subsequent quality assessment and determination.

In contrast, traditional metallographic measurements have some limitations, such as only being able to measure two points of weld penetration depth, being unable to comprehensively evaluate depth fluctuations, and being unable to effectively identify local under-welding or over-welding. In the meantime, ICI technology adopts an online non-contact detection method, performing full-module, full-weld seam inspection. It can identify local under-welding larger than 1mm or 12°, and by setting qualified ranges for monitoring, it effectively prevents batch under-welding issues.

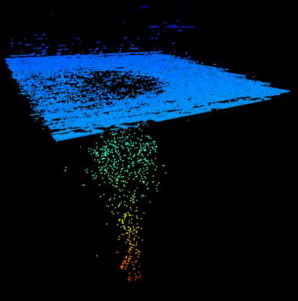

The more stable the welding process, the more concentrated the keyhole locations. ICI technology captures real-time depth data of each weld point during the welding process, helping to determine keyhole positions and presenting them in clear 3D images. This allows operators to intuitively understand the morphology of the welding area and the depth of each weld point, providing strong support for adjusting and controlling welding quality.

It is worth noting that welding stability depends not only on the state of the laser and welding head but also on the entire equipment, such as the amount of defocus, gas blowing, dust extraction, incoming material conditions, and clamping factors. Therefore, to ensure the accuracy of ICI technology, attention needs to be paid to factors such as speed and overlap rate variations caused by oscillating welding, changes in absorption due to material temperature rise, and changes in welding conditions, etc. Improving the overall stability of the welding equipment and enhancing the accuracy of keyhole positioning will further increase the detection reliability of ICI technology and enhance the manufacturing quality of battery modules.